current location : Home » categoires :

How to Choose the Right Color Sorting Machine for Your Business

How to Choose the Right Color Sorting Machine for Your Business

Selecting the ideal color sorting machine requires balancing precision, adaptability, and industry-specific needs. At HTsorter, our industrial plastic optical sorting solutions are designed to tackle diverse challenges, from recycling streams to high-purity manufacturing demands. Here’s why our systems stand out in a competitive market.

|

|

|

Precision for Diverse Applications

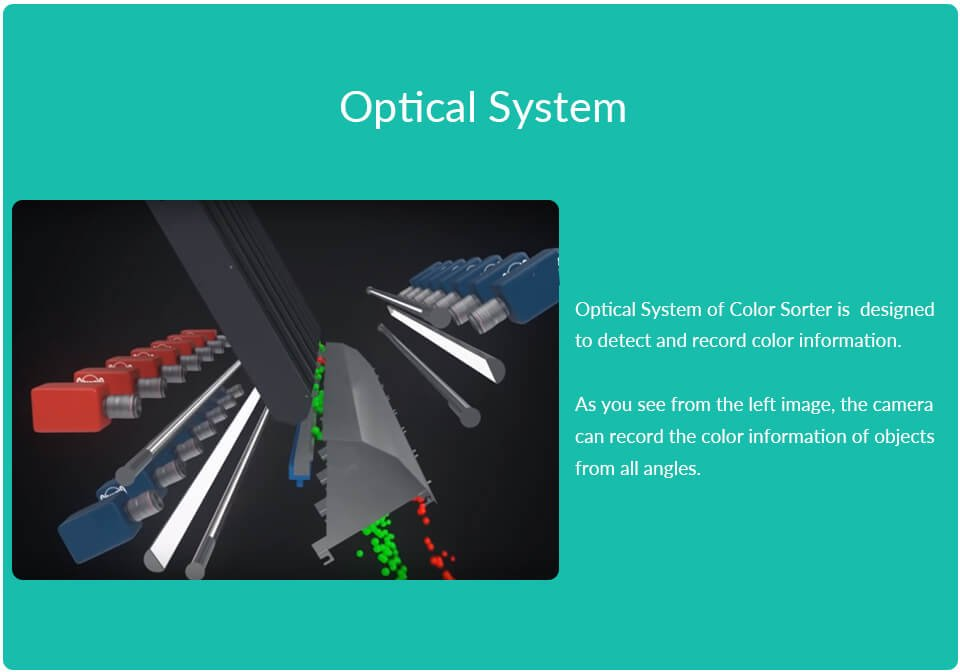

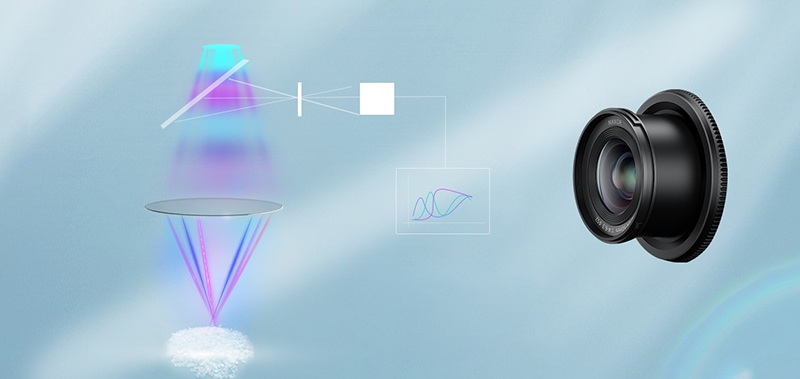

Every industry faces unique sorting challenges. For example, in the recycling sector, mixed plastics and black polymers historically posed difficulties. HTsorter’s optical sorters leverage near-infrared (NIR) spectroscopy and AI-driven imaging to distinguish materials by molecular composition, not just color. This technology ensures accurate separation of PET, PVC, and HDPE with 99.9% efficiency, even in complex waste streams.

For food-grade plastic recycling, compliance with stringent safety standards is non-negotiable. Our plastic sorting machines for food-grade applications integrate hyperspectral imaging to detect micron-level contaminants, ensuring outputs meet FDA and EU regulations—critical for packaging and medical-grade plastics.

Speed and Scalability Without Compromise

High-volume operations demand machines that keep pace. HTsorter’s automated plastic pellet color separation systems process up to 8 tons per hour, thanks to adaptive air-jet ejection and real-time monitoring. This efficiency is vital for industries like injection molding, where downtime translates to lost revenue. Modular designs allow seamless upgrades as production scales, whether for startups or large enterprises.

Smart Integration for Future-Ready Operations

Beyond hardware, HTsorter’s IoT-enabled platforms offer remote diagnostics and predictive maintenance, minimizing unplanned downtime. Operators can adjust parameters via user-friendly interfaces, while cloud analytics track performance trends—key for optimizing workflows in dynamic environments.

|

|

Why HTsorter?

- Compliance-Driven: Built-in protocols ensure outputs meet global safety standards, particularly for sensitive sectors like food and healthcare.

- Sustainability Focus: Reduce material waste by up to 30% through precise sorting, aligning with circular economy goals.

- Versatility: From rigid industrial plastics to flexible films, our systems handle diverse materials and shapes.

- 24/7 Global Support: Technical assistance ensures uninterrupted operations, regardless of location.

Choosing HTsorter means investing in innovation and reliability. Our solutions don’t just sort materials—they elevate efficiency, compliance, and profitability while contributing to a sustainable industrial future.

prev How Intelligent Color Sorters Are Revolutionizing Industrial Processing

next Unleashing Power and Efficiency The 800kW Scroll Air-Cooled Chiller Redefines Industrial Cooling