current location : Home » categoires :

How Intelligent Color Sorters Are Revolutionizing Industrial Processing

How Intelligent Color Sorters Are Revolutionizing Industrial Processing

In the fast-paced world of industrial manufacturing and recycling, precision and efficiency are non-negotiable. At HTsorter, we’re leading this transformation with cutting-edge solutions like plastic pellet sorting machines for the recycling industry, optical sorters for plastic granules in manufacturing, and high-speed plastic pellet color sorters for injection molding. These innovations are redefining quality control, sustainability, and profitability across sectors.

|

|

Precision Meets Sustainability

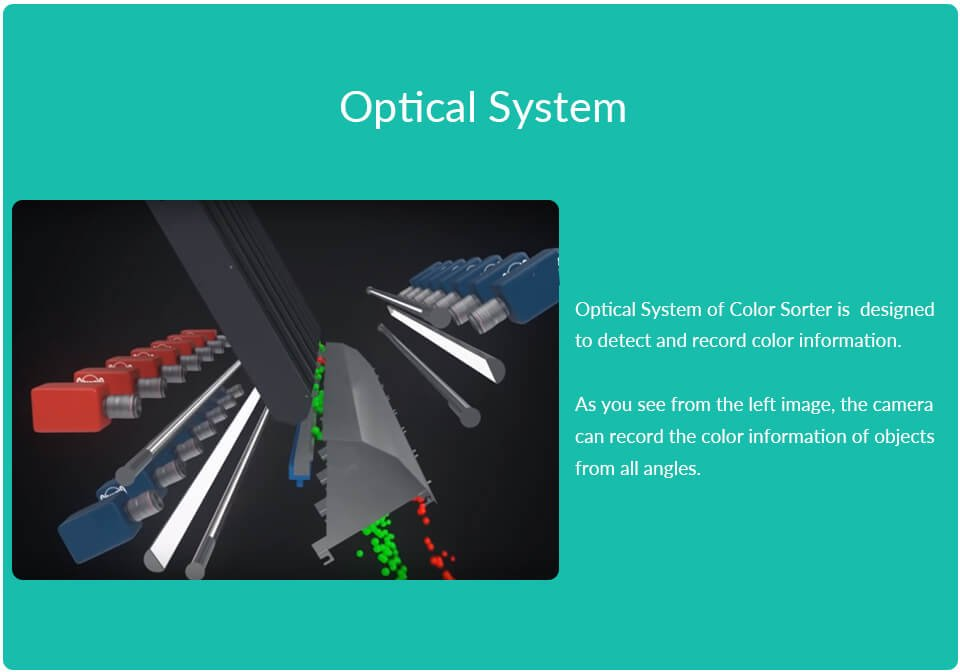

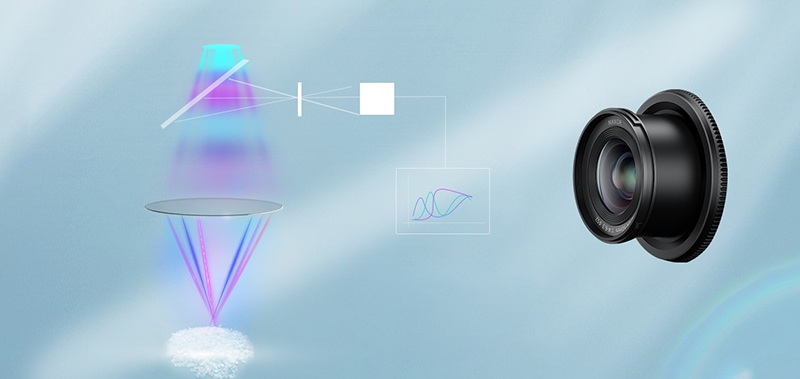

Traditional sorting methods often struggle with mixed plastics or subtle color variations, leading to material waste and higher costs. Modern optical sorters equipped with AI-driven imaging systems, like those in HTsorter’s plastic pellet color sorters, analyze materials at microscopic levels. By identifying defects or contaminants in real time, these systems ensure only high-quality pellets move forward in production—critical for industries like injection molding, where material consistency directly impacts product integrity.

Adapting to Complex Recycling Streams

The recycling industry faces unique challenges, such as sorting black plastics or mixed polymers. HTsorter’s plastic pellet sorting machines integrate near-infrared (NIR) spectroscopy and multi-core image processing to distinguish materials by chemical composition. For example, our systems can separate PET from PVC in mixed waste streams, transforming low-value recyclables into pure, reusable pellets—boosting circular economy goals while reducing landfill dependence.

|

|

Speed Without Compromise

In high-volume manufacturing, downtime is costly. HTsorter’s high-speed color sorters process up to 6 tons of materials per hour with 99.99% accuracy, thanks to advanced CCD sensors and adaptive air-jet ejectors. This efficiency is vital for injection molding facilities, where rapid material turnover and flawless pellet quality are essential to meet tight production schedules.

Smart Technology for Smarter Workflows

Beyond hardware, HTsorter’s machines feature IoT-enabled platforms for remote monitoring and predictive maintenance. Operators can adjust sorting parameters via intuitive interfaces, while cloud-based analytics track performance trends. This adaptability ensures seamless integration into existing production lines, minimizing training time and maximizing ROI.

Why Industries Trust HTsorter

- Versatility: From rigid bottles to flexible films, our sorters handle diverse materials.

- Energy Efficiency: Low-power designs reduce operational costs by up to 30%.

- Global Support: 24/7 technical assistance ensures uninterrupted workflows.

Intelligent color sorters are no longer a luxury—they’re a necessity for industries aiming to balance productivity, sustainability, and competitiveness. With HTsorter’s plastic pellet sorting machines, optical sorters, and high-speed systems, businesses can future-proof their operations while contributing to a cleaner, more efficient industrial landscape.

prev Say Goodbye to Space Constraints Compact Chillers for Modern HVAC Challenges

next How to Choose the Right Color Sorting Machine for Your Business