What are the requirements for the positioning of the impeller of the multi-stage mid-open pump?

The impeller positioning of multi-stage horizontal split pump is the core key step in the assembly process, which is directly related to the running efficiency, vibration noise and service life of the pump. The core goal of the positioning is to ensure that the exit center of all impellers is in a straight line and the inlet center of the guide vane is aligned.

The following are the detailed multi-stage middle open pump impeller positioning method, steps and matters needing attention.

1、 Core Principle

The position of each impeller in the multi-stage pump is not fixed by the axial distance of the bushing, but by the axial total displacement of the rotor.

The total axial displacement of rotor components refers to the axial movement distance of the entire rotor (including the shaft, all impellers, balance disc, etc.) from one extreme position to the other extreme position without installing thrust bearings.

The purpose of positioning is to ensure that the axial thrust caused by temperature rise and pressure during pump operation will not cause friction between the impeller and stationary components (such as pump casing and inlet ring). It also ensures the alignment of the impeller outlet with the guide vane inlet at each stage to achieve better hydraulic performance.

2、 Location methods and procedures

The "rotor trial fitting method" or "measurement and calculation method" is commonly used, both of which are fundamentally similar. Below are the detailed steps combining both methods:

Step 1: Preparation and Initial Assembly

Cleaning and Inspection: Thoroughly clean all pump components including the shaft, impellers, bushings, and balance discs, ensuring no burrs or damage.

Measure the impeller width and sleeve length separately (if applicable) and record the data. This will facilitate cross-validation in subsequent steps.

Initial assembly: Install the first-stage impeller, subsequent impellers, shaft sleeves, and balance discs sequentially onto the pump shaft. Do not tighten the fixing nuts (e.g., balance disc nuts) initially, allowing all components to maintain axial sliding relative to the shaft.

Step 2: Measure the total rotor clearance

The assembled rotor (without bearings) is hoisted into the lower half of the pump housing.

A dial gauge is installed at one end of the pump shaft (usually the drive end), with its head pointing toward the shaft's end face, to measure axial displacement.

Manually push the entire rotor toward the pump's drive end (DE) until it can no longer be moved (e.g., when the first-stage impeller contacts the pump body). Then, reset the dial gauge to zero.

Manually pull the entire rotor toward the non-driving end (NDE) of the pump until it can no longer be moved (e.g., when the final-stage impeller or balance disc contacts the pump body). The dial gauge reading at this point is the 'total rotor runout.' Record this value as S_total.

To ensure accuracy, perform multiple push-pull cycles and verify the stability of the dial gauge reading.

Step 3: Align the impeller position

After the total run-off is measured, the ideal working position of the impeller should be in the middle of the total run-off.

Calculate the center position: Push the rotor to the midpoint of the total stroke. For example, if the total stroke S_total is 4.0 mm, the center position is 2.0 mm from the driving end's limit position to the non-driving end.

Verify alignment (core check):

Method A (traditional method): Using a feeler gauge or long feeler gauge, measure the gaps between the center of each impeller outlet and the corresponding guide vane inlet center in all directions. Under ideal alignment, these gaps should be essentially equal. If the gap deviation of any stage is excessive, it indicates that the axial position of that impeller stage is incorrect.

Method B (marking method): On the middle plane of the pump body, mark the center of each guide vane inlet with red lead or marker pen. Then rotate the rotor to check if the outlet edges of each impeller align with these marks. This is the most intuitive and effective method.

Adjustment: If misalignment is detected, it may require fine-tuning the bushing length or inserting shims between the impeller hubs. For mature designs, this step is usually unnecessary, as proper total runout ensures natural alignment.

Step 4: Fix the rotor and set the working stroke

After the center position is determined, the rotor component must be locked in this relative position.

Fixed balance disc: When the rotor is aligned, tighten the locking nut on the balance disc. This is a critical step to secure the relative position of internal rotor components. After tightening, recheck the total runout to ensure it remains essentially unchanged.

The thrust bearing is installed to give the rotor a predetermined position and to bear the residual axial force.

Set the working stroke:

After the installation of thrust bearing, the axial movement range of the rotor will be limited, and the limited movement range is called "working clearance".

Typically, the working clearance is set to approximately half of the total clearance (for example, 2mm when the total clearance is 4mm), with equal gaps maintained on both sides (toward DE and NDE).

The axial movement of the rotor should be within the working stroke range when the rotor is rotated, which can be verified by dial indicator.

III. Key Considerations

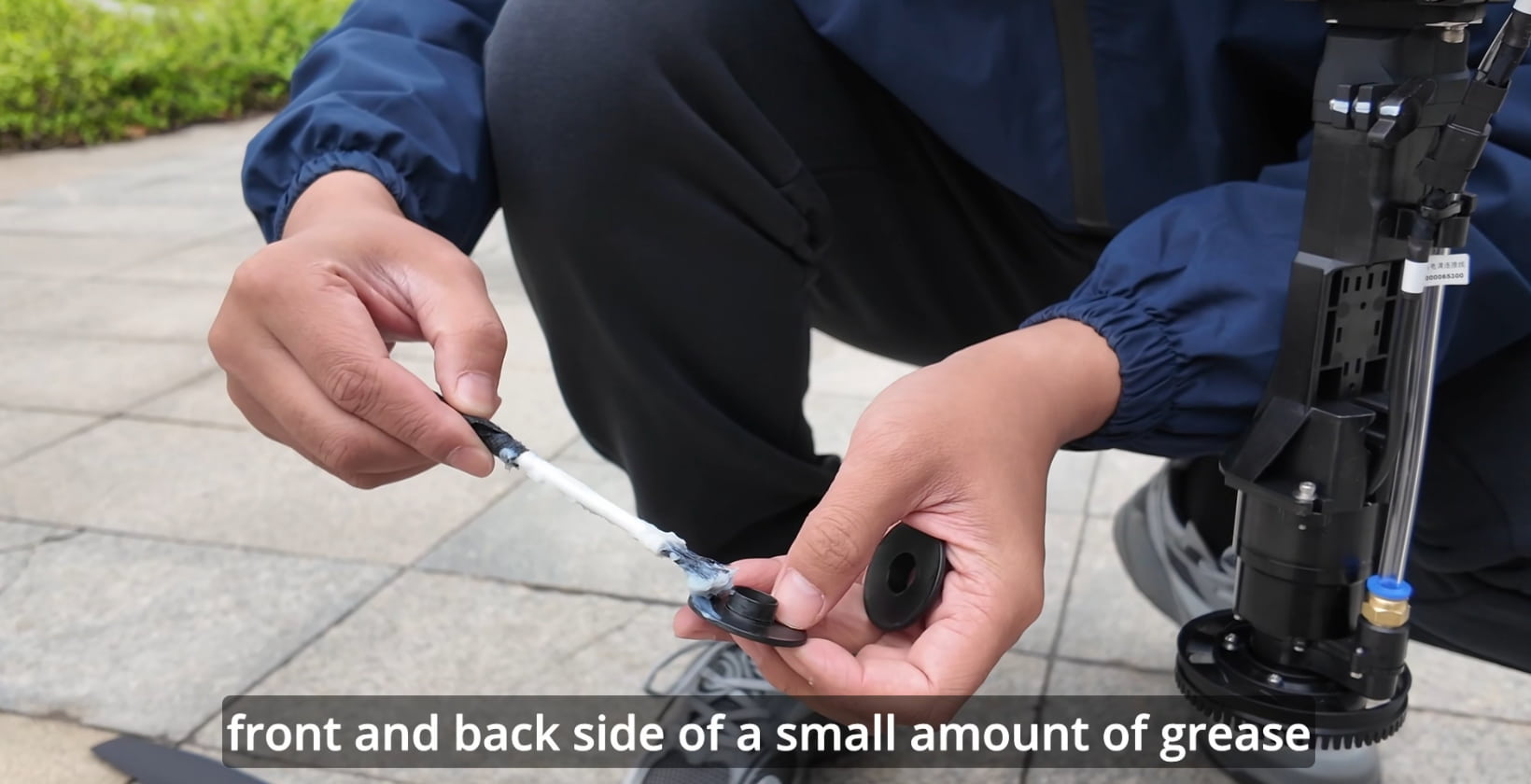

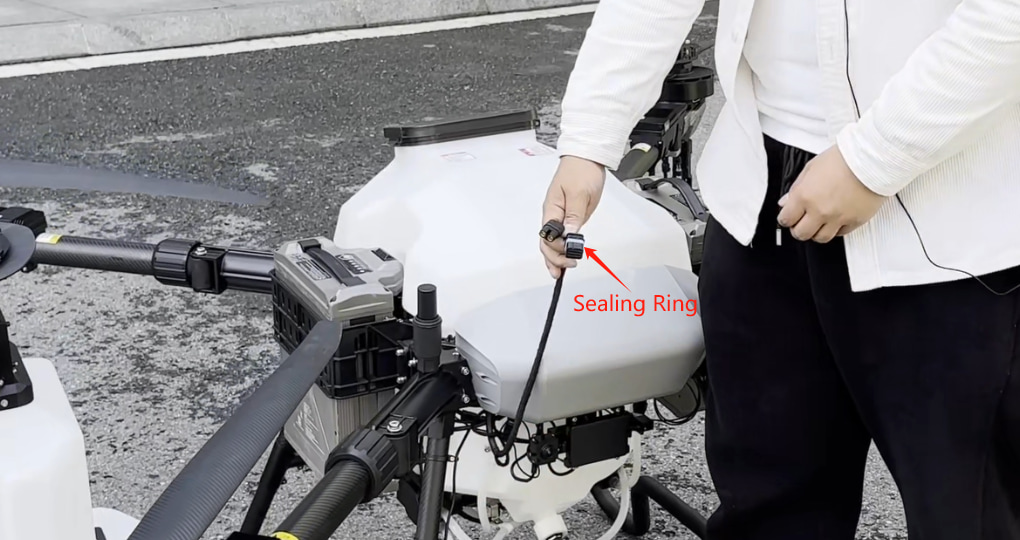

1. Cleaning and Lubrication: All mating surfaces and O-rings must be thoroughly cleaned and coated with a suitable lubricant (e.g., molybdenum disulfide) to facilitate assembly and prevent seizing.

2. Marking and recording: All measured data, including total stroke and working stroke, should be meticulously documented for future maintenance and fault analysis.

3. Symmetrical tightening: When closing the pump cover, the bolts on the middle opening face should be tightened symmetrically according to the manufacturer's specified sequence and torque to prevent pump housing deformation.

4. Handwheel Test: After final assembly, manually rotate the rotor to verify smooth and uniform rotation without any friction or jamming.

5. Adhere to manufacturer specifications: Different pump models may have unique designs and requirements. The above methods are general guidelines, but in practice, the manufacturer's installation and maintenance manual should be the primary reference.

...