1. Basic Concepts of Color Fastness in Textiles

Color fastness, in simple terms, refers to the ability of textiles to maintain their color stability during use. It encompasses multiple aspects, including resistance to washing, friction, light, sweat, sweat stains, and sunlight exposure. Different color fastness indicators represent how textiles perform under various environmental conditions. For example, washing fastness refers to the degree of color change after repeated washing of garments; while lightfastness reflects the degree of color fading under sunlight.

The quality of colorfastness directly impacts the product's lifespan and aesthetic quality. If colorfastness is insufficient, issues such as color bleeding, discoloration, or fading may arise, which not only affect appearance but may also lead to customer dissatisfaction or returns. Conducting scientific and standardized colorfastness testing has become a standard practice within the industry.

2. The Process and Standards for Color Fastness Testing

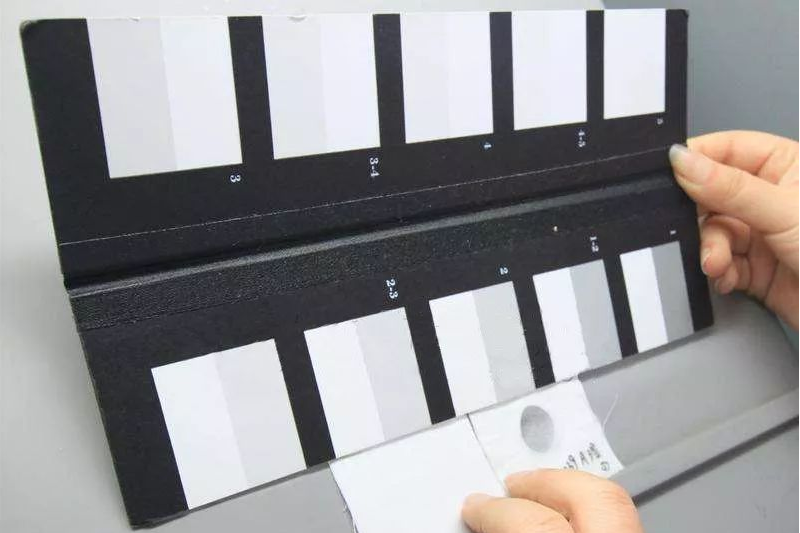

Color fastness testing typically follows national or industry-established standards to ensure the scientific rigor and comparability of the testing process. The general process consists of four main steps: sample preparation, setting test conditions, actual testing, and evaluation of results.

(1) Sample Preparation: Representative samples are selected from a batch to ensure that test results reflect overall product quality. Samples should be cut and marked according to specifications to avoid contamination or damage.

(2) Test Condition Setup: Appropriate standards and methods are selected based on the test requirements. For example, water resistance testing may follow the washing procedures specified in national standards, while lightfastness testing uses specific light sources and exposure times.

(3) Actual Testing: Conduct tests on samples in a strictly controlled laboratory environment following standard procedures. For example, simulate real-life conditions such as washing, friction, and exposure to sunlight, and observe changes in sample color.

(4) Result Evaluation: Use professional color difference meters or visual comparison for assessment. Colorfastness grades are assigned according to standard classifications, where “Grade 1” indicates excellent colorfastness and “Grade 5” indicates poor colorfastness.

3. The Importance of Color Fastness Testing for Textiles

(1) Textiles with poor color fastness often experience dye shedding, and some low-quality dyes may enter the human body through skin contact or the respiratory tract, causing allergies, inflammation, or even long-term health risks. Testing can indirectly screen out products where dyes are firmly bonded to fibers, reducing the risk of harmful substance release.

(2) Colorfastness testing can precisely identify issues in production, such as improper dye selection during dyeing or incorrect fixation process parameters (e.g., poor temperature or pH control). Companies can adjust their processes based on test results to improve product stability and reduce batch defect rates.

(3) Outdoor clothing requires lightfastness, medical textiles require disinfectant resistance, and sportswear requires sweat-light composite colorfastness. These specialized testing requirements drive companies to develop targeted dyeing technologies, thereby enhancing product value and market competitiveness.

Textile colorfastness testing not only ensures basic quality and safety but also promotes industry upgrading and trade facilitation. Its importance spans the entire lifecycle of a product, from production to consumption, making it a crucial pillar for the high-quality development of the textile industry.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com

...