In the valve bag making machine sector, Gachn Group's new generation FK008-III valve bag making machine, with its numerous innovative technologies and superior performance, has become an industry leader. It not only breaks through traditional limitations in key processes such as bag making, transfer, bag opening, and conveying, but also demonstrates significant advantages in technical parameters and equipment configuration, providing businesses with an efficient, stable, and cost-effective production experience

Core Innovative Technologies Break Through Traditional Production Bottlenecks

Gachn Group's valve bag making machines feature innovative designs in several key mechanisms, effectively resolving numerous issues with traditional equipment.

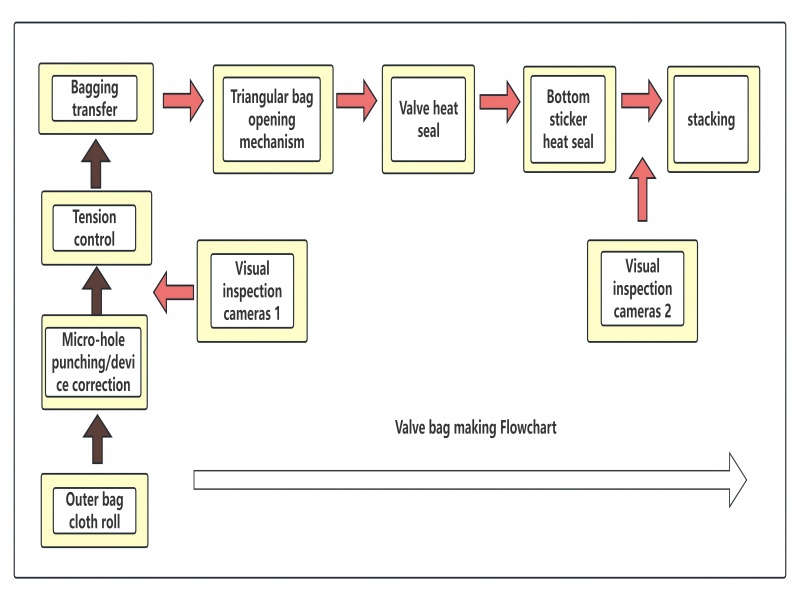

In the bag transfer process, the Gachn Group utilizes a proprietary vacuum suction bag steering mechanism, enabling high-speed, vertical bag transfer for rapid and stable operation. Unlike the "claw-type" bag steering mechanisms used by other manufacturers, Gachn Group possesses its own core technology and intellectual property, avoiding patents held by renowned international equipment manufacturers and eliminating the risk of intellectual property infringement lawsuits.

The triangular bag opening mechanism is a further highlight, lacking consumable suction cups, significantly reducing ongoing maintenance costs. This mechanism utilizes a combination of negative pressure and a conveyor system to efficiently open the bag bottom while reducing noise and ensuring efficient and stable operation. Similarly, this proprietary core technology avoids international patents, eliminating the risk of intellectual property infringement lawsuits and providing peace of mind for manufacturers.

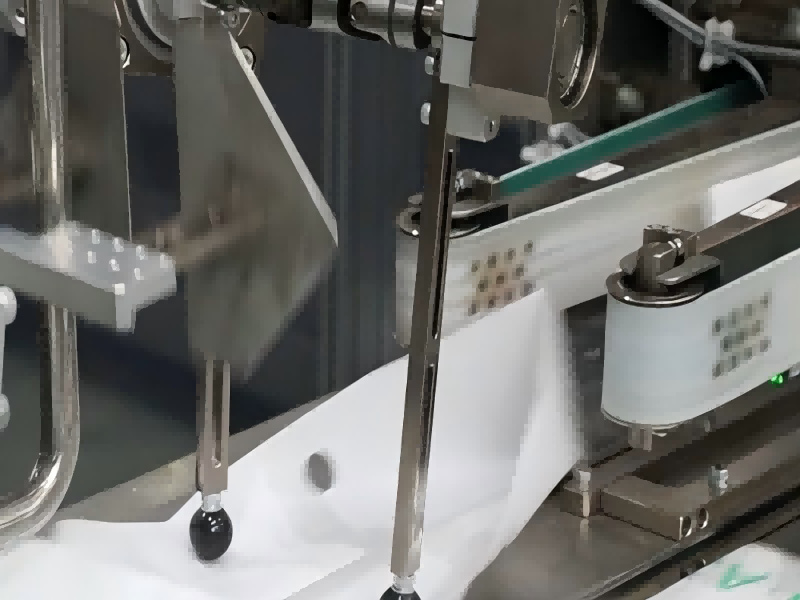

In terms of suction roller transfer, the bottom tape belt conveyors used by other valve bag making machines on the market are prone to bending, resulting in scrap. Furthermore, the higher the production speed, the more severe the kinking problem becomes. The belts also wear easily, making replacement difficult. Gachn Group's innovative suction roller conveyor mechanism is less prone to corner bending, significantly improving bag yields, enhancing equipment stability, and reducing production costs. This feature is unique to Gachn Group and is patented.

In addition, Gachn Group utilizes a professionally designed heat-sealing welding mechanism and unique technology, equipped with three hot air mechanisms, to ensure uniform air blowing and consistent dimensions. Servo-controlled switching of the air blow reversing axis allows for precise control of the welding on/off timing. Compared to other manufacturers' pneumatic cylinder control mechanisms, this system offers higher welding quality, precise adjustment of the air blow angle, and flexible adjustment of the heat seal width without requiring downtime, significantly enhancing production flexibility and efficiency.

Excellent Technical Parameters, Meeting Diverse Production Needs

The Gachn Group FK008-III valve bag making machine excels in bag making specifications and equipment parameters, adapting to diverse production needs.

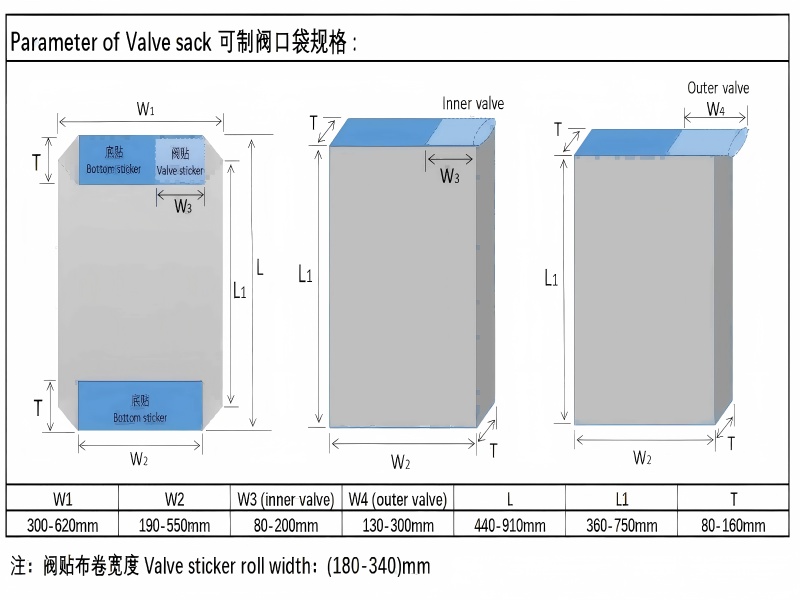

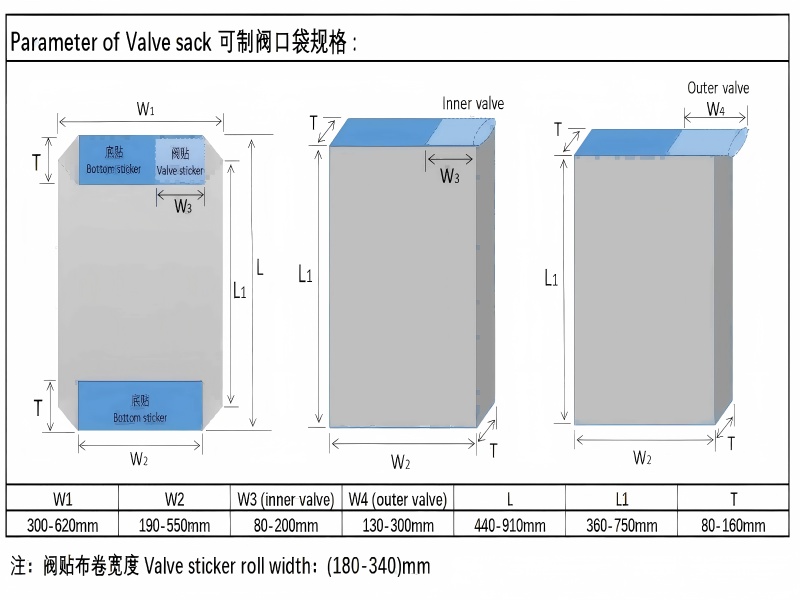

It offers a wide range of bag specifications, with bag center length (L) ranging from 330-730 mm, bag width (W) from 300-620 mm, and bottom width (W1) from 80-120 mm, respectively. The valve opening length ranges from 80-200 mm.

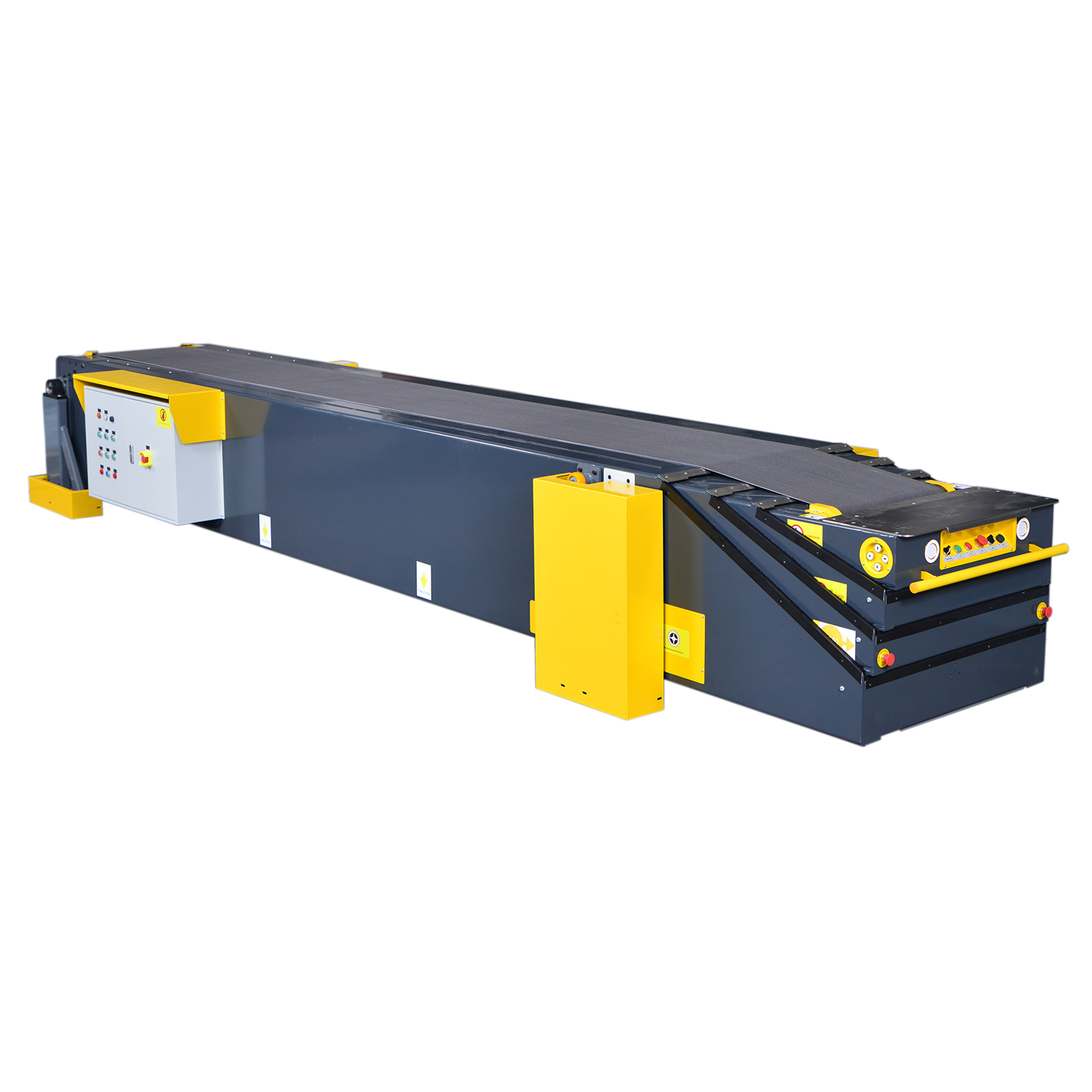

The machine's specifications are equally impressive, with the main unit measuring 12.0 m (L) x 7.5 m (W) x 2.5 m (H), featuring a height adjustment mechanism at the bottom. The machine weighs approximately 17,000 kg. It utilizes a 3-phase, 380 Vac ±5%, 50 Hz, three-phase, five-wire system (CE standard), with an installed capacity of approximately 150 kW. The bag-making speed reaches a stable 130 bags/minute, with a maximum operating speed of 140 bags/minute.

Gachn Group's new-generation FK008-III valve bag bag-making machine integrates a visual inspection and waste removal system with core bag-making technology, creating a truly fully automated AI-powered closed-loop production system. Equipped with a 4K line-array infrared high-speed industrial camera and a black-and-white high-speed industrial camera, the visual inspection system accurately detects cosmetic defects in bags at a speed of 120 bags/minute. With a waste rejection rate of ≥96.5% and a false rejection rate of <0.15%, it enables real-time monitoring and intelligent screening of bag quality. Its detection logic is efficiently integrated with the core bag-making technology. When the visual system identifies a defective bag, a signal is instantly fed back to the bag-making unit's servo control system, triggering a cutting mechanism to precisely separate the defective bag. Simultaneously, the bag transfer unit's vacuum suction and dual servo drive systems immediately adjust the conveying rhythm to ensure that subsequent qualified bags are not affected.

Superior Equipment Configuration Ensures Stable and Efficient Operation.

The Gachn Group FK008-III valve bag making machine is comprised of numerous high-quality components, all working together to ensure stable and efficient operation.

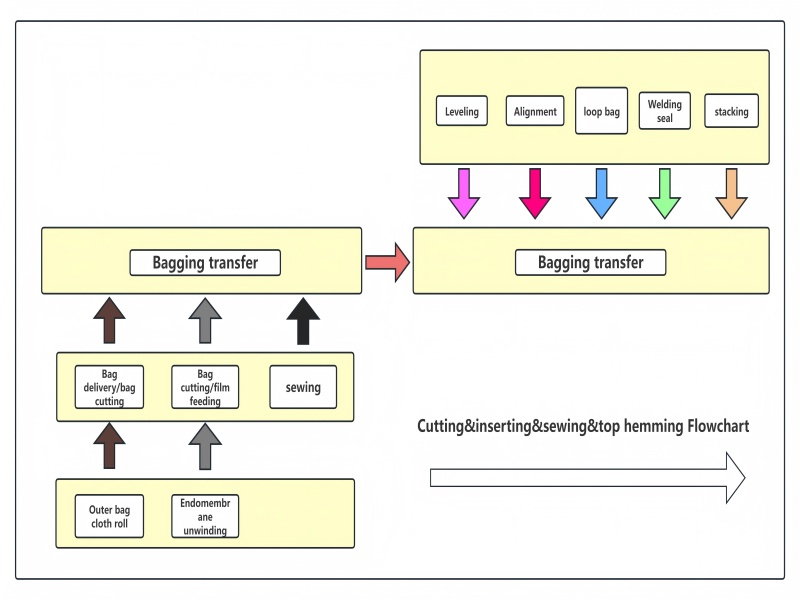

The machine features a comprehensive range of components, including 16 main components: a bag unwinder, micro-perforating device, unwinding traction device, bag-making device, and bag transfer device. The bag unwinder utilizes a passive unwinding mechanism, with the material unwinding driven by a traction motor. It is equipped with a magnetic powder brake, an air shaft, a swing arm for lifting the material, an end-of-roll alarm, and a floating tension bar, ensuring stable and reliable material unwinding and easy operation.

The micro-perforating device:utilizes a modular assembly system for micro-perforating needle rollers. Damage to any part requires only the corresponding module to be replaced, making it economical and cost-effective. The micro-perforation size adjustment mechanism utilizes a screw and handwheel design for easy adjustment. The unwinding traction device is independently controlled by a servo motor, and the clamp rollers are opened and closed by a manual valve-controlled cylinder, simplifying material threading.

The bag-making unit:includes mechanisms for pulling material, color mark alignment, and rear-end cutting. The color mark position is adjustable, and bag-making can be performed in two modes: color mark alignment and fixed-length. It also features a bag-ready detection function and manual bag-making functions. The bag-transferring unit utilizes a vacuum negative pressure system and dual servo segmented control to ensure stable, timely, and reliable bag movement. A photoelectric detection system generates an alarm and stops the bag-making section if transfer fails.

The bag-opening unit:includes an opening unit and a mouth-opening unit. The opening unit utilizes a separate servo conveyor combined with negative pressure blower control, while the mouth-opening unit is also controlled by a separate servo, ensuring stable and widest opening. The forming unit consists of a triangular forming unit and a belt conveyor. The triangular forming unit is efficient, stable, and has an adjustable width, while the belt conveyor prevents the opening from rebounding.

The welding unit:utilizes an ultra-high-temperature heating gun with adjustable temperature, equipped with thermocouple temperature detection and a power-off protection device. A servo-controlled steering axis controls the airflow direction, and the nozzle width is adjustable. The folding unit uses multiple folding plates to create a fixed folding path, and the folding width is adjustable via a lead screw. The conveyor system for valve and bottom stickers incorporates multiple mechanisms, ensuring simple and reliable unwinding. It is equipped with a web-correcting device, and the cutter roller and material transfer mechanisms are independently controlled by servo motors, ensuring accurate cutting length and welding position. The finished product stacking conveyor features counting and stacking functions, with adjustable parameters. Protective devices comply with relevant regulations to ensure production safety. The visual inspection and waste removal system, electrical system, and pneumatic system are also well-equipped, providing strong support for equipment operation.

In addition, the equipment's electrical configuration and mechanical components are imported, high-quality international brands, such as Schneider and Weidmüller for low-voltage power distribution, German Schneider for PLC, servo, and touch screen, Panasonic for sensors, and Taiwan's Xinbao for servo planetary reducers, ensuring stable performance. All machined parts are surface-treated, exposed parts are made of high-quality materials, and transmission components are made of special steel that has undergone quenching and tempering treatment, ensuring equipment durability.

Comprehensive service and support ensure worry-free production.

Professional on-site technical training provides hands-on instruction on equipment installation and commissioning. After the equipment is installed and commissioned, we will dispatch experienced technicians to the customer's factory to provide face-to-face technical guidance. The training covers key points such as equipment operation procedures, parameter adjustment techniques, common fault diagnosis and repair methods. During the training, the customer is required to arrange for one to two technicians to participate to ensure that relevant personnel master all equipment operation and maintenance skills, laying a solid foundation for stable equipment operation.

Efficient remote team support for rapid response to needs. In addition to on-site services, Gachn group has also established a professional technical team to provide comprehensive remote after-sales service. Whether customers have questions about equipment operating parameter settings, troubleshoot unexpected minor problems, or require technical consultation during production, they can contact our remote service team by phone, video, or other means. Leveraging their in-depth knowledge of the equipment, the team will provide timely solutions and remotely assist in troubleshooting and resolving issues, minimizing production downtime caused by equipment issues and ensuring continuous production.

Gachn Group's new generation FK008-III valve bag making machine, with its innovative technology, superior performance, sophisticated configuration, and comprehensive service, provides valve bag manufacturers with an efficient, stable, and cost-effective solution, leading the industry to new heights of production. Choosing Gachn Group guarantees efficient production.

...